It's a familiar and frustrating moment for homeowners from Plano to Frisco: you turn the knob on your electric stove, ready to get dinner started, but one of the burners just won't heat up. My first piece of advice? Don't panic. In most cases, the culprit is something simple and relatively easy to fix.

More often than not, the problem is a bad connection where the burner plugs into the stove or a faulty burner coil itself. These components take a lot of abuse, heating up and cooling down day after day. It's only natural they wear out. Sometimes, the fix is as simple as wiggling the burner to make sure it's seated properly. Other times, you might be looking at a failed control switch or a problem with the terminal block, but we'll get to that.

Your Quick Guide to a Non-Working Stove Burner in Allen, TX

This guide is designed to help you quickly figure out what's going on. For many homeowners I've helped in Allen and Plano, a dead burner is a very manageable DIY repair. We'll start with the most obvious checks and then dig a little deeper to pinpoint what's gone wrong.

Common Failure Points in Electric Stoves

When an electric stove burner goes cold, the issue almost always traces back to one of four key parts. Getting a handle on what these parts do is the key to a fast diagnosis.

Here’s a quick rundown of the usual suspects:

- The Burner Coil: This is the part you see—the spiral heating element. With enough use, the internal filament can simply burn out, breaking the electrical circuit. If you see any blisters, bubbles, or breaks on the coil's surface, you've found your problem.

- The Burner Socket (or Receptacle): Think of this as the outlet the burner prongs plug into. A loose connection here is incredibly common. Look closely for any charring, scorch marks, or corrosion on the terminals. That's a sure sign of a bad connection that's stopping the electricity from getting through.

- The Infinite Switch: This is the guy behind the control knob, the one that tells the burner how hot to get. When this switch fails, it can't send any power to the element, no matter how high you turn the dial.

- The Terminal Block: This is the central hub where the main power cord from your wall connects to all the stove's internal wiring. It's less likely to be the problem for a single burner failure, but damage here can cause all sorts of issues, sometimes affecting the whole appliance.

To help you get started, here's a table that breaks down the most common symptoms and where you should look first.

Common Stove Burner Problems and First Steps

This table will help you quickly identify the most likely cause of your stove burner issue and point you toward the right first step.

| Symptom | Most Likely Cause | Your First Action |

|---|---|---|

| One burner isn't working at all | A loose connection or a burned-out coil. | Unplug the stove. Swap the dead burner with a working one to see if the burner or the socket is the problem. |

| Burner only works on high heat | A faulty infinite switch. | The switch has likely failed and can no longer regulate power levels. It will need to be replaced. |

| Visible sparks or scorch marks at the socket | A bad connection in the burner socket. | Immediately unplug the stove. The socket and possibly the burner prongs need to be inspected and likely replaced. |

| Blisters or bubbles on the burner coil | The burner coil has failed internally. | The burner element has reached the end of its life and must be replaced. |

Using this quick-check table can save you a lot of time and guesswork.

Running through these initial checks will put you on the fast track to a simple DIY repair. Even if you decide not to tackle it yourself, you'll have specific, helpful information to share when you call a trusted appliance repair professional in McKinney or Frisco, which always leads to a faster and more efficient service call.

Essential Safety Checks Before You Begin Any Stove Repair in Frisco

Before you even think about picking up a screwdriver, let’s talk safety. This isn't like unplugging a toaster. An electric stove runs on a powerful 240-volt circuit—that's double what your standard wall outlet carries, and it demands respect. Mishandling it is seriously dangerous.

Let me be crystal clear: turning the burner knob to "Off" does absolutely nothing to make the stove safe to work on. The appliance is still very much live and poses a significant risk. You have to kill the power at the source.

Completely Disconnect the Power

The only safe way to start this job is by heading to your main electrical panel, or breaker box. You're looking for the breaker that controls the stove. It won't be a standard one; it’s a beefy double-pole breaker that looks like two switches fused together.

Grab that switch and flip it firmly to the "OFF" position. If your panel isn't perfectly labeled (and many aren't), you'll need to verify you got the right one. Go back to the stove and try to turn on a burner or the oven light. If everything is dead, you’re good to go. For any homeowner in Frisco, this step is non-negotiable.

Pro Tip: Slap a note on the breaker box that says something like, "Do Not Touch – Working on Stove." It’s a simple trick, but it can stop a well-meaning family member from accidentally flipping the power back on while your hands are in the machine.

Prepare Your Workspace and Tools

With the power confirmed off, it's time to get your work area ready. Electrical safety is about more than just the breaker.

Here’s what you need to do every single time:

- Make Sure Everything is Dry: Water and electricity are a lethal mix. Wipe up any spills on the floor around the stove, and make sure your hands are completely dry before you start.

- Gear Up: A good pair of thick, dry work gloves is a must. They’ll protect you from sharp metal edges inside the appliance and add a layer of insulation. Safety glasses are never a bad idea, either.

- Use Insulated Tools: If you have them, grab screwdrivers and pliers with rubber or plastic handles. They’re designed specifically to reduce the risk of shock if you were to make a mistake and touch something you shouldn't.

Even though a burner isn't working, it’s still part of a system that could have hidden faults. Faulty wiring and improper maintenance are serious hazards. In 2023 alone, electrical devices were connected to 2,260 fires, and stoves were involved in 860 of those incidents. You can learn more about appliance fire safety statistics and their causes to understand the risks.

For anyone in McKinney or North Dallas tackling this project, taking these few minutes to prepare can be the difference between a successful fix and a trip to the emergency room.

Pinpointing the Exact Cause of the Failure in Your McKinney Home

Alright, with the power to the stove completely cut off, it's time to play detective. Guessing games won't help you here, but a little methodical troubleshooting will lead you right to the source of the problem. The quickest and easiest way to start is with a simple swap test.

This little trick is your best first move because it tells you so much right away. Just take the burner coil that isn't working and swap it with an identical one from another spot on the stove that you know works perfectly.

If the "bad" burner suddenly heats up in the new spot, you know the coil itself is fine. The problem is somewhere in the stove's wiring at the original location. But, if the "bad" burner still refuses to heat up in its new home, congratulations! You've found the culprit: a dead burner coil. That’s the best-case scenario—it’s a cheap and incredibly easy fix.

Inspecting the Burner Socket and Connections

If the swap test told you the burner coil is good, your next suspect is the burner socket (sometimes called the receptacle). From my experience working on stoves across North Dallas, this is a super common point of failure. You'll need to lift the cooktop to get a good look at it.

You're hunting for any obvious signs of heat damage or a bad connection. Keep an eye out for:

- Scorch Marks: Any black or brownish discoloration on the plastic socket is a dead giveaway of overheating.

- Corrosion: Look for rust or that classic greenish-blue gunk on the metal terminals.

- Physical Damage: Check for any visible cracks, melted plastic, or warping on the socket's housing.

Finding any of these tells you the connection has been failing for a while, creating resistance that generates enough heat to melt plastic and prevent power from ever reaching the coil.

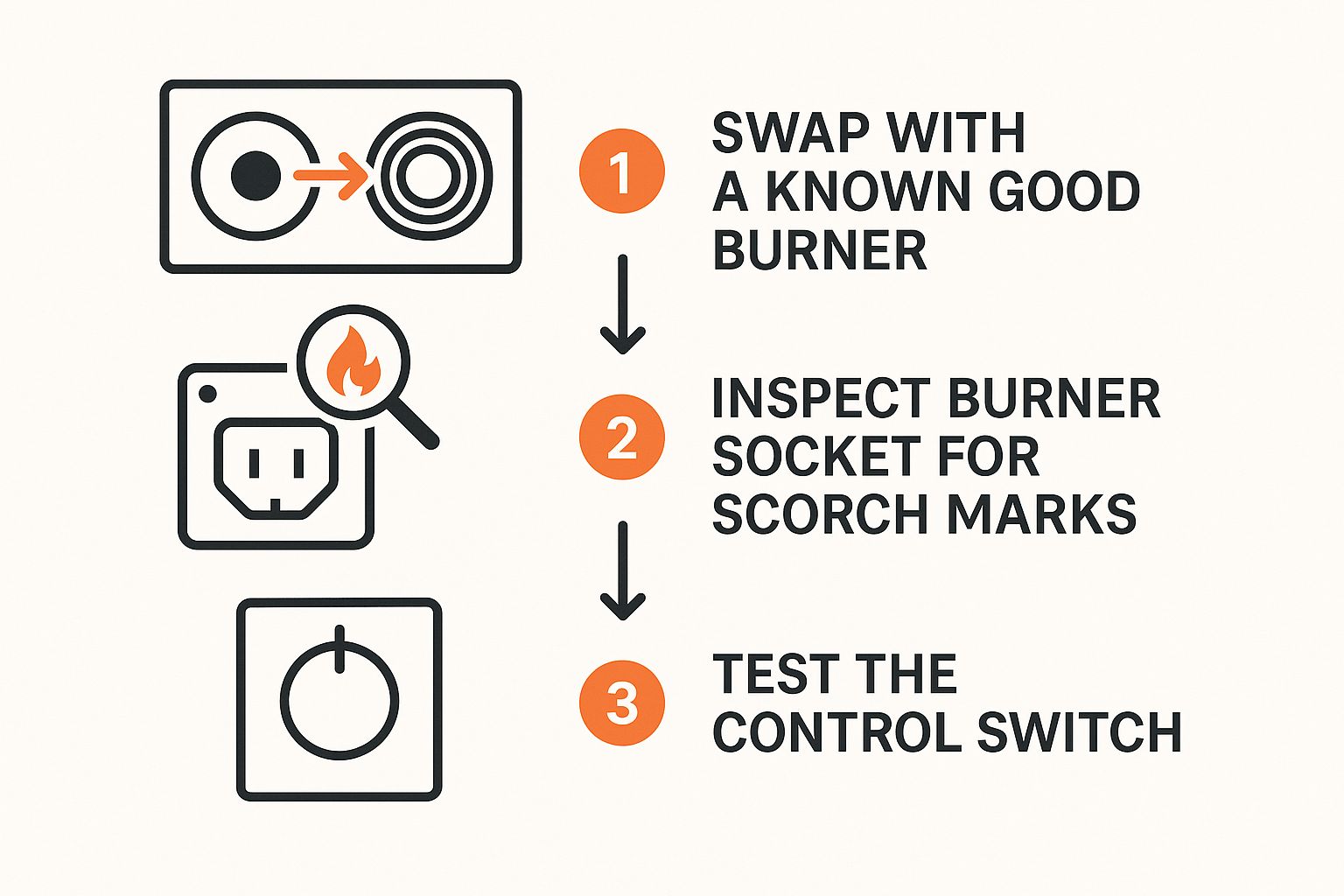

To keep the diagnostic path clear, this infographic lays out the whole process.

As you can see, by checking the coil, then the socket, then the switch, you can’t really go wrong. You’ll find the faulty part one way or another.

Beyond the Socket: The Infinite Switch

So, what if the burner coil passed the test and the socket looks pristine? Now we have to look deeper into the stove's controls. The next component in line is the infinite switch—that’s the part behind the control knob you turn to set the temperature.

When an infinite switch goes bad, it can fail in a couple of ways. Sometimes it gets stuck on the highest setting, but more often, it just dies and stops sending any power to the burner. We see this all the time on service calls in Frisco; the burner is completely dead, but the coil and socket look perfect.

Testing a switch requires a multimeter to check for continuity, which might be a step too far for most DIY repairs. If you've gotten this far down the checklist and still haven't found the problem, it’s a pretty solid sign that it's time to call in a pro. And while you're thinking about appliance repairs, it might be worth checking on other issues. We have another great guide on what to do when your oven is not heating to the correct temperature.

Practical DIY Repairs You Can Confidently Tackle in Celina

Alright, you've pinpointed the problem, so now comes the satisfying part—the fix. You might be surprised to hear that the most common reasons an electric stove burner gives up the ghost are well within the grasp of a handy homeowner. Getting your hands a little dirty here can save you a decent chunk of change and the hassle of waiting for a repair technician.

More often than not, the issue boils down to one of two things: the burner coil itself or the socket it plugs into. The good news is that both are surprisingly simple to replace with just a few common tools and the right parts.

Replacing a Faulty Burner Coil

If your swap test pointed to a dead burner coil, congratulations. You've landed on the easiest repair of them all. This one usually requires no tools whatsoever and is about as difficult as changing a lightbulb.

It’s pretty much as straightforward as it sounds. Just lift the old coil out, give it a firm pull to unplug it from the socket, and then plug the new one in. The real secret to success here is getting the correct replacement part. Before you do anything else, find your stove’s model number—I usually find it on a small metal plate or sticker inside the oven door frame or sometimes on the back. With that number, a quick online search or a trip to an appliance parts store will get you the exact match.

Don’t get tempted by a coil from another brand that looks like it will fit. It might seem close enough, but mismatched burners can have different wattage ratings. This can lead to anything from poor cooking performance to damaged wiring or even a fire hazard. It's not worth the risk.

How to Replace a Burner Socket

Now, what if you saw scorch marks or other damage on the burner socket (also called the receptacle)? This fix is a little more involved, but it's still completely doable. You’ll likely just need a screwdriver and maybe a pair of needle-nose pliers.

First things first: power off at the breaker. No exceptions. From there, you'll need to lift the entire cooktop to get to the wiring underneath. Most electric stoves have a hinged top that you can prop open. You’ll see the socket held in place by a mounting bracket with two wires connected to it. Just unscrew the bracket, carefully disconnect the wires from the old, damaged socket, and connect them to the new one.

I always tell people to snap a quick photo with their phone of how the wires are connected before disconnecting anything. It’s a simple trick that takes two seconds and eliminates any guesswork when you’re hooking up the new socket. Once it's wired and secured, you can lower the cooktop, plug the burner coil back in, and head to the breaker to restore power and test your handiwork.

For more projects like this, feel free to check out some of our other great DIY stove fix guides.

Ensuring a Safe and Lasting Repair

Fixing the immediate problem is great, but making sure it doesn't happen again is even better. A properly working stove is a cornerstone of a safe kitchen. Faulty electric burners are, unfortunately, a major cause of house fires. In fact, data reveals that a staggering 67% of reported home electric range fires start with cooking on the burners, and that risk skyrockets when parts are old or failing.

You can read the full report on residential stovetop safety to get the full picture, but the takeaway is clear: maintenance matters. For any homeowner in Celina or Plano, double-checking that these electrical connections are clean and secure is a critical step in keeping your home safe.

Knowing When to Call the Pros in North Dallas

There's a real satisfaction in fixing something yourself, I get it. But with electric stoves, there's a fine line between a simple DIY win and a project that can get dangerous—fast. Knowing when to put the tools down and call a professional isn't admitting defeat; it's the smartest move you can make to protect yourself and your home.

Some issues with an electric burner just aren't meant for a weekend warrior. Once your troubleshooting takes you past the easy-to-swap coil and its socket, you're getting into the stove's internal wiring. That’s professional territory.

Red Flags That Mean "Stop"

Think of these symptoms as your stove's way of telling you it needs an expert. If you spot any of these, it's time to call for backup. This isn't just friendly advice; these are serious safety warnings.

- A Persistent Burning Smell: Don't confuse this with the faint odor of a brand-new coil. I'm talking about a sharp, acrid electrical smell coming from inside the stove. That's a classic sign of fried wiring and a major fire hazard.

- Melted Wires or Scorch Marks: When you lift the cooktop, do you see any plastic insulation that looks melted or gooey? Any black scorch marks around the main terminal block? This indicates a severe electrical fault that needs immediate attention from a pro.

- A Glitchy Control Board: If several burners are acting up at once, or the digital display is on the fritz, the problem is likely the stove's main control board. Swapping one of those out is a complex job, not a simple part replacement.

- Any Problem Requiring a Multimeter: To test an infinite switch or check the terminal block, you need a multimeter. More importantly, you need to know exactly how to use it on a live 240V circuit without causing a short or getting a nasty shock. This is not the place to learn on the fly.

A trained technician can bring the right diagnostic tools to safely pinpoint these deeper electrical problems in just a few minutes. It saves you the headache and completely removes the risk of injury or making the problem worse.

The Smartest (and Safest) Choice for Plano & McKinney Residents

Look, if the burner coil is visibly broken or the socket is cracked, go for it! That's a perfect DIY job. But when the problem is buried deep inside the stove's circuitry, calling a professional is the right call every time. For those in McKinney and nearby, our team has the equipment to test these components safely and accurately. You can see how we handle expert stove repair in Plano and why some jobs just need a professional touch.

Don't forget the risks. The National Fire Protection Association (NFPA) found that the rate of fire injuries is a staggering 3.6 times higher in homes with electric ranges versus gas ranges. That statistic alone shows why you can't afford to get a repair wrong. If you want to dig into the data, you can read the full NFPA research on home cooking fires.

When you're in doubt, always put your safety first.

Common Questions About Ailing Electric Burners

When an electric burner goes on the fritz, homeowners tend to run into the same handful of questions. Based on countless service calls all over the North Dallas area, we've compiled the answers to the questions we hear most often about cooktop troubles.

Why Did My Burner Just Quit on Me?

A burner that was working perfectly yesterday but is dead today almost always signals one of two things. Most of the time, the heating element inside the coil has simply burned out. Think of it like a lightbulb filament—after countless cycles of heating up and cooling down, it eventually just gives up and snaps, which breaks the circuit.

The other common reason is much simpler: a loose connection. The prongs that plug the burner into the stove can get wobbly over years of cooking and cleaning. Before you jump to conclusions, your very first move should be to make sure the burner is seated snugly and pushed all the way into its socket.

Should I Repair This Old Stove or Just Get a New One?

If it's just a single faulty burner, repairing it is almost always the smarter financial move. A new coil or receptacle is a relatively small purchase, usually under $50, which is a tiny fraction of what a new stove would cost. A simple, inexpensive fix can easily breathe several more years of life into your current appliance.

Now, if you're dealing with a different scenario—say, multiple burners are failing, the oven is also acting up, or you're looking at a bigger electrical issue like a bad control board—it might be time to think about a replacement. This is especially true if your stove is more than 10 years old. We often help homeowners in Plano and Allen weigh the costs to make the best decision for their budget.

Can I Just Swap in a Burner From Another Stove?

I really have to advise against this. It's a tempting shortcut, I know. A burner from a different brand might look identical and even seem to click right into place, but it's a gamble. Each one is engineered with very specific wattage and voltage ratings for the stove it was made for.

Trying to use a mismatched burner can create a cascade of problems:

- Wonky Heating: It probably won't heat up properly, giving you hot spots and unevenly cooked food.

- Stove Damage: You could overload the wiring or fry the control switch inside your stove—a much more expensive repair.

- Fire Hazard: Worst of all, an incompatible part can overheat and become a serious fire risk.

Always, always use replacement parts that are specifically made or approved for your exact stove model. It’s the only way to guarantee a safe and reliable fix.

If you've hit a wall and your stove issue seems more complex than a quick DIY fix, ThumbUp.Pro is ready to step in. Our certified technicians deliver prompt, expert appliance repair across Allen, Plano, Frisco, McKinney, and the greater North Dallas area. Don't let a bad burner throw a wrench in your dinner plans—book an appointment online and you'll get $20 off your service.