When your ice maker suddenly quits, it's easy to assume the worst. But more often than not, the culprit is a simple, easy-to-fix issue. I've seen it hundreds of times serving homes in Plano and Frisco—the problem is usually a raised feeler arm, a paused cycle, or a clogged water line. You can check all of these in minutes, no tools required.

Your First Checks for a Faulty Ice Maker in North Dallas

The moment the ice stops dropping, many homeowners in Plano and Frisco start dreading a costly repair bill. Before you pick up the phone, take a deep breath. A few quick checks can often get things running again. Modern refrigerators have features designed to pause ice production that are surprisingly easy to trigger by accident.

The goal here is to rule out the obvious stuff first. This initial once-over takes less than five minutes and could save you the time and expense of a service call. Let's walk through the most common reasons an ice maker just stops working.

Check the Feeler Arm or On/Off Switch

Believe it or not, the most frequent reason an ice maker stops producing is because it's been inadvertently switched off. Every ice maker has a mechanism to tell it when the bin is full, and this same control can be accidentally activated.

- Feeler Arm: A lot of models have a metal wire, which we call a "feeler arm." When that arm is locked in the up position, the ice maker is off. Simple as that. Gently push it down. If it won't stay down, the ice bin might be overfull, or a stray cube could be jamming it.

- On/Off Button or Switch: Newer units might have a toggle switch, a slide button, or an option on the digital control panel. Make sure it's set to "On." It’s incredibly easy to bump this switch when grabbing a frozen pizza.

This is the very first thing our technicians check on service calls throughout Allen and the surrounding North Dallas areas. It's almost always the quickest fix in the book.

Rule Out a Paused Cycle or Clogged Filter

If the feeler arm is in the right position and the unit is on, the next place to look is at other common interruptions. A "pause" feature or a clogged water filter will stop ice production just as effectively as flipping a switch.

Many refrigerators with water dispensers have a pause function, which can get hit by mistake, especially after changing the filter. Speaking of filters, an old or clogged one can slow water flow to a trickle, preventing the ice maker from ever filling its mold.

Pro Tip from the Field: Most manufacturers recommend replacing your water filter every six months. If your water dispenser is running slow, that's a dead giveaway the filter is clogged and probably affecting your ice maker, too.

Before you start worrying about water lines and solenoids, make sure you’ve covered these basics. The table below gives you a quick rundown of these initial steps.

Quick Diagnostic Checklist for Your Ice Maker

Here's a handy summary of the most common and easily fixable reasons your ice maker has called it quits. Run through these before calling for help.

| Potential Cause | What to Check | Simple Solution |

|---|---|---|

| Unit is Off | Feeler Arm Position or On/Off Switch | Gently lower the feeler arm or flip the switch back to "On". |

| Paused Cycle | Control Panel Display | Look for a "Pause" light or symbol on the screen and deactivate it. |

| Clogged Water Filter | Water Dispenser Flow | Replace the filter if water dispenses slowly or the filter is over 6 months old. |

Checking these three things resolves a surprising number of "broken" ice maker situations. If you've tried all of them and you're still not getting ice, it's time to move on to slightly more involved checks.

Diagnosing Common Ice Maker Issues in Allen, TX

So, you’ve checked that your ice maker is actually on and the filter is good to go, but you’re still not getting any ice. Now it’s time to dig a little deeper into the things that can go wrong. Here in North Texas, from McKinney to Celina, one of the first things we look at is the freezer temperature. It's a surprisingly common culprit.

Your freezer has a sweet spot. For the ice maker to do its job properly, the temperature needs to be right between 0°F and 5°F. If the freezer is too warm, the water in the mold never freezes solid enough, so the harvest cycle never gets the signal to start. On the flip side, if you set it too cold (below 0°F), you can actually freeze the water supply line itself, creating an ice dam that stops everything cold.

Understanding the Ice Maker Cycle

To figure out what’s broken, it helps to understand how the whole thing is supposed to work. It’s a simple, elegant process—when it’s working.

First, an electric water inlet valve at the back of the fridge opens for just a few seconds to fill the ice mold. Once a little thermostat inside the ice maker senses the water has frozen solid, it kicks off the next phase. A motor then turns the ejector arms, which pop the finished cubes out and into the bin. The feeler arm then drops down to check if the bin is full before starting the whole process over again.

A breakdown at any point in that chain stops production entirely. For example, if you hear a constant buzzing or humming, that often points to a water inlet valve that's trying to open but can't. A clicking or grinding noise could mean the ejector arms are stuck on a stubborn cube.

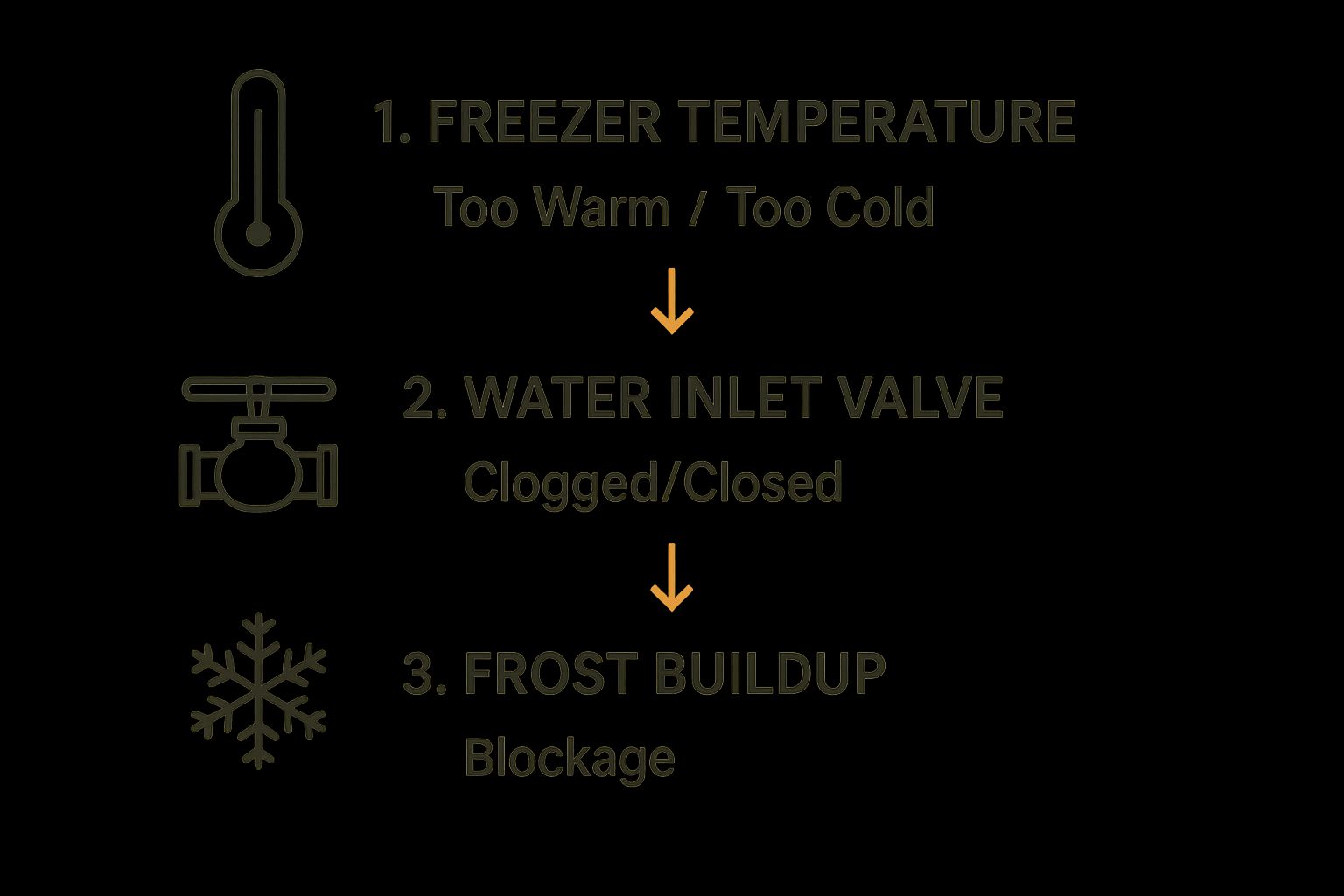

This visual guide walks through the most common failure points we find on service calls.

As you can see, the process is pretty logical. You start with the simple stuff, like the freezer's environment, before moving on to specific mechanical parts.

Common Mechanical Failures in Allen and Plano

In our experience helping homeowners in Allen and Plano, a few parts tend to fail more than others. Two of the most frequent offenders are the water inlet valve and the ice maker's own internal thermostat.

- The Water Inlet Valve: This little part is the gatekeeper for the water. It’s located on the back of your fridge, and over time, mineral deposits from our hard Texas water can clog it up. If you can hear a faint hum but see no water in the ice mold, this valve is almost certainly your problem.

- The Ice Maker Thermostat: This isn't the thermostat that controls your freezer temperature. It's a tiny sensor inside the ice maker unit itself, and its only job is to detect when the water has turned into solid ice cubes. If it goes bad, the ice maker never gets the "go" signal to harvest the ice, and the cycle just stalls out.

These kinds of mechanical issues are pretty universal. Across North America, the high demand for convenient appliances like ice makers means there's a greater need for maintenance to keep them running smoothly.

If you want to dive even deeper into these issues and a few others, check out our complete ice maker troubleshooting guide. It has more detailed steps you can try yourself before making the call for a professional repair.

Trying a Few DIY Ice Maker Fixes

Alright, so you've checked the easy stuff and your ice maker is still giving you the silent treatment. It’s time to roll up your sleeves. The good news is that many of the most common ice maker problems can be fixed with basic tools and a bit of know-how.

But first, a crucial safety warning. Before you do anything else, you absolutely must unplug the refrigerator and shut off its water supply valve. I can't stress this enough. It’s the only way to prevent a nasty electrical shock or an accidental flood in your kitchen. Once you’re disconnected, you can safely investigate a few of the most frequent issues we see.

How to Thaw a Frozen Water Line

One of the most common reasons an ice maker quits working is a frozen water line. It happens all the time, especially if your freezer temperature is set just a little too cold or if the line gets crimped behind the unit.

You'll suspect this is the problem if you notice no water at all—or maybe just a few pathetic drips—making it to the ice mold. The fix is pretty simple: grab a hairdryer.

Set the hairdryer on low or medium heat and gently wave it back and forth along the water line. You'll want to warm up the section inside the freezer and the part that connects to the back of the refrigerator.

A Quick Word of Caution: Whatever you do, don't get impatient and reach for a heat gun or an open flame. You’ll melt the plastic tubing, which will cause a leak and turn a simple fix into a major repair. A hairdryer and some patience are all you need.

After a few minutes of gentle warming, the ice blockage should melt. You can then plug the fridge back in, turn the water on, and see if water starts flowing to the ice maker again.

Swapping Out the Refrigerator Water Filter

I know we mentioned this earlier, but it’s so often the culprit that it’s worth a closer look. Think of a clogged water filter as a dam blocking the river. Over months of use, it gets packed with sediment and minerals from your water, slowing the flow to a trickle.

Thankfully, changing the filter is a breeze on most models. They're usually located inside the fridge, down in the front grille, or tucked behind a small panel.

- Find the filter: If you can't spot it right away, your owner's manual will show you where it's hiding.

- Remove the old one: Most have a push-button release or just require a simple quarter-turn to unlock. It's a good idea to have a small towel handy to catch a few drips.

- Pop in the new one: Just insert the new filter and twist or push it to lock it into place.

- Flush the system: Finally, run about a gallon of water through the dispenser. This clears out any trapped air and loose carbon bits from the new filter.

Making this a regular six-month habit can save you a ton of trouble. It’s not just good for your ice maker; it keeps your drinking water fresh, too. If you want to dive deeper into filter issues, we cover more about common refrigerator ice maker problems on our blog.

How to Reset Your Ice Maker

Sometimes, all your ice maker needs is a simple reboot. An electrical flicker from a storm or a power outage can be enough to throw its cycle off track. A quick reset can often kick it back into gear.

How you do this really depends on your refrigerator's make and model. Many have a tiny pinhole reset button that you can press with a paperclip. Others have a simple on/off switch. Some of the newer Samsung and LG models even have a "test" button that, when held down, forces the ice maker through a harvest cycle.

Your best bet is to check the appliance manual for the specific instructions for your unit. If you've tried these DIY fixes and your ice maker is still on strike, it’s probably a sign of a more complex issue that needs a professional eye.

Time for a Deeper Dive: Tackling Complex Ice Maker Problems

So, you've checked the easy stuff—the water line isn't frozen, the filter is clean, and the shut-off arm is in the right position—but you still have no ice. This is usually when the real head-scratching begins. We’re moving past simple blockages and into the core components: the parts that make your ice maker tick, whir, and freeze.

Most of the time, the culprit is a failed electrical or mechanical part. Think of things like the water inlet valve, the ice maker’s internal thermostat, or the ejector motor that pushes the cubes out. Telling them apart can feel like a guessing game, but your ice maker often leaves clues. For example, if you hear the motor trying to run—a faint click or a strained hum—but nothing happens, you're likely looking at a problem with the ejector mechanism. Power is getting there, but the gears aren't turning.

Is It an Electrical or Mechanical Problem?

Your first job is to figure out if the ice maker is even getting power. This is the fork in the road for your diagnosis. Some ice makers have a little light that tells you they’re on, but many don't. If yours is the silent, dark type, you'll have to rely on your ears. Listen closely for any sound at all when it's supposed to be running a harvest cycle.

If you hear absolutely nothing—no hum, no click, no whir—it's a good bet you have an electrical issue on your hands. The unit isn't even getting the message to start.

On the other hand, if you do hear signs of life, the problem is almost certainly mechanical.

- Hear a motor straining? If you hear noises but see no action, you could have a jammed gear or a motor that's simply given up.

- A constant, low hum? This often points to the water inlet valve. It's stuck "on," trying to open but failing.

- The tray is bone dry? If you hear the unit cycle through its motions but no water ever enters the mold, the water inlet valve is again the prime suspect.

These symptoms pop up across almost every brand. In fact, industry data consistently shows that faulty sensors, temperature problems, and motor failures are among the most common reasons ice makers break down. You can see just how widespread these issues are by checking out some findings on ice maker technical issues. Knowing this can be a huge help when you’re trying to explain the problem to a technician in McKinney or Frisco.

The Notorious Water Inlet Valve

Let's talk more about that water inlet valve. It’s a small, simple part with a big job: it's an electrically-controlled gate that opens just long enough to fill the ice mold with water. Because it's constantly working and exposed to water, it's a very common point of failure, especially in areas with hard water where mineral deposits can build up.

When a valve goes bad, it usually fails in one of two ways. It either gets stuck closed, which means no water gets to the ice maker, or it gets stuck open (or just doesn't close all the way). The second scenario leads to the ice mold overfilling, spilling water into your ice bin and creating a giant, solid block of ice where your nice, neat cubes should be.

Know When to Call a Pro: If your investigation points toward an electrical problem or a major component like the inlet valve, this is usually a good place to pause. Messing with live wiring can be dangerous, and guessing which part to replace can get expensive fast. Our technicians in Allen and Plano carry the right diagnostic tools to safely and accurately figure out exactly what's wrong.

Knowing When To Call an Appliance Pro in Plano and McKinney

Tackling a DIY repair can feel great, but there’s a fine line between a satisfying fix and a costly mistake. Knowing your limits is the most important part of the job—it can save you from causing more damage, creating a safety hazard, or even voiding your warranty. Some problems are just clear signs that it’s time to put the tools down and call a professional.

For instance, if you find a puddle of water growing under your fridge, don’t hesitate. A significant leak can quickly cause serious damage to your flooring and cabinets. The same goes for any electrical red flags. If you hear a distinct buzzing sound, smell something burning, or the fridge keeps tripping your circuit breaker, these are non-negotiable warnings. Those issues need a trained eye to diagnose and fix safely.

Signs You Need Professional Help

Diving into a complex repair without the right training is a recipe for disaster. If the fix requires you to start dismantling major parts of the refrigerator or mess with sealed system components, it’s best to step back. Our technicians, who help homeowners from Plano to Celina, have the specialized tools and experience to handle these intricate jobs safely.

It’s definitely time to call in a professional if you’re seeing any of these:

- Significant water leaks: A puddle on the floor is a classic sign of a failed water line or valve.

- Electrical issues: Any buzzing, burning smells, or tripped breakers are serious warnings that shouldn't be ignored.

- Major component disassembly: Taking apart the core of the refrigerator is risky for even the most confident DIYer.

- Suspected refrigerant leaks: Refrigerant is a hazardous material that only certified pros should ever handle.

Modern appliances are getting more and more complex. It's no surprise when you see how big the industry has become—the global ice maker market was valued at USD 5.3 billion and is expected to reach USD 7.4 billion by 2033. All that growth means more advanced technology, which makes a professional diagnosis more critical than ever when your ice maker quits. You can learn more about these trends on the global ice maker market.

Trying to save a few bucks on a service call can easily backfire, leading to a much bigger bill if you damage another part or just get the diagnosis wrong. For homeowners here in North Dallas, calling a pro is often the fastest and most reliable path to a real solution.

Protecting Your Appliance and Your Home

At the end of the day, it’s all about safety and efficiency. A professional technician doesn't just show up with the right parts; they have the diagnostic equipment to pinpoint the exact cause of the failure. This ensures the job is done right the first time.

If you're in Allen, TX, and facing a refrigerator issue that feels over your head, our team can provide a same-day fridge repair service to get everything back to normal without the guesswork.

Your Top Ice Maker Questions Answered for Allen and Plano Residents

Even after running through all the troubleshooting steps, you probably still have a few questions. It's only natural. Our technicians get asked the same things all the time by homeowners in Plano and Allen when their ice maker decides to take a break.

Let's clear up some of the most common questions we hear every day. This will give you a better idea of what to expect after a repair and what certain symptoms, like those tiny ice cubes, are really telling you.

How Long Until I Get Ice After a Repair?

This is the big one everyone asks. After you’ve fixed an issue or just reset the unit, you'll need a little patience. An ice maker typically needs about 90 minutes to two hours to churn out its first batch of cubes. That gives the freezer enough time to get back down to its ideal temperature (around 0°F) and lets the machine run through a full harvest cycle.

Now, don't start worrying if it takes a bit longer. But if you’ve been waiting for four hours and still see an empty ice bin, that’s a red flag. It usually means there's another problem preventing the cycle from kicking off.

Why Are My Ice Cubes Suddenly Tiny or Hollow?

Seeing small, hollow, or cloudy ice is almost always a sign of a water flow issue. Simply put, the ice mold isn't getting enough water to fill up completely before the freezing process begins. From our experience, this is almost always caused by one of two culprits.

- A Clogged Water Filter: This is the number one reason, hands down. An old filter can seriously choke off the water supply.

- A Kinked or Frozen Supply Line: Take a peek behind your fridge. That thin water line can easily get pinched or, if it's too cold, freeze solid.

Your first move should be to replace the water filter. If that doesn't do the trick for your McKinney home, the supply line is the next thing to inspect. On rare occasions, it could even be low water pressure in your whole house.

A healthy ice maker produces solid, clear cubes. If you're consistently getting small or hollow ice, your machine is telling you the water supply is getting blocked somewhere.

Can I Still Use My Fridge If the Water Line Isn't Hooked Up?

Yes, absolutely. Your refrigerator and freezer will work just fine without the water line connected. Many people who don't use the ice maker or water dispenser run their fridges this way.

The critical thing to remember, though, is to turn the ice maker itself off. Look for a switch or just lift the metal feeler arm until it locks in the "up" position. If you forget and leave it on, the machine will keep trying to pull in water that isn't there. This can eventually burn out the water inlet valve, creating a completely avoidable repair job later on.

When you've hit a wall and can't get that ice maker running, it's time to bring in a pro. ThumbUp.Pro delivers fast, dependable appliance repair for homeowners across Allen, Plano, Frisco, McKinney, and Celina. Our certified techs will pinpoint the real problem and get your appliance back in business, usually in just one visit. Book online at https://thumbup.pro and save $20 on your repair.